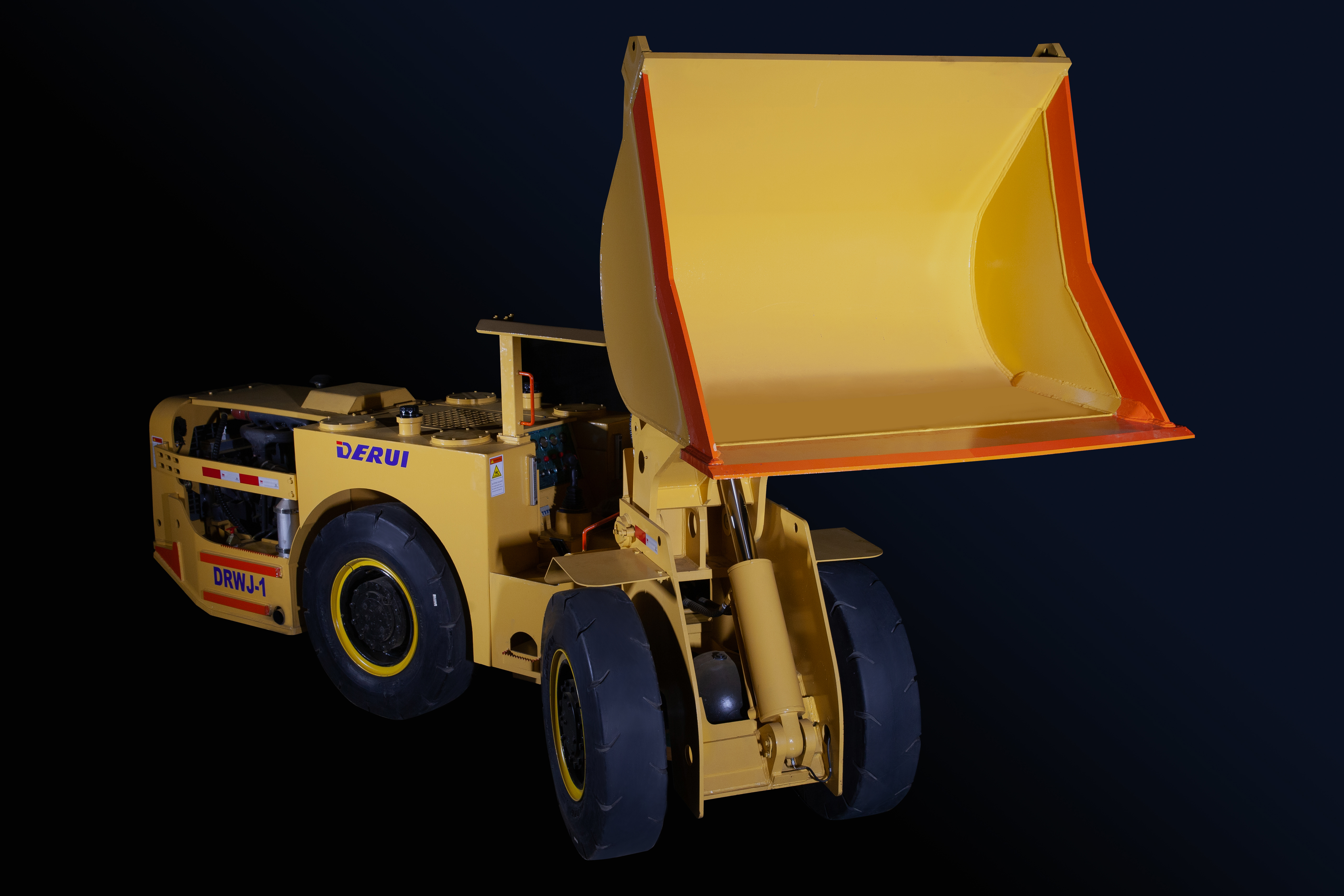

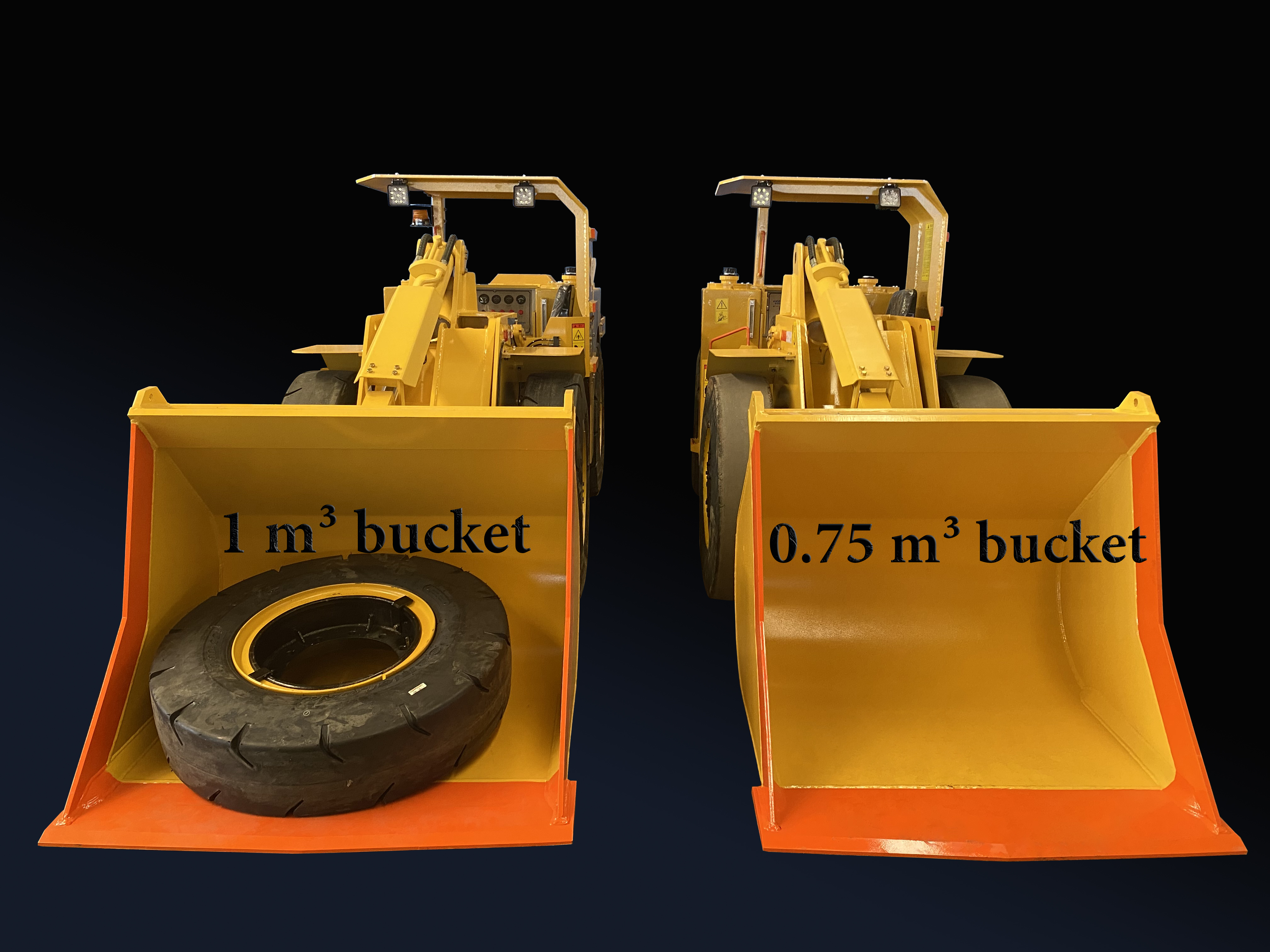

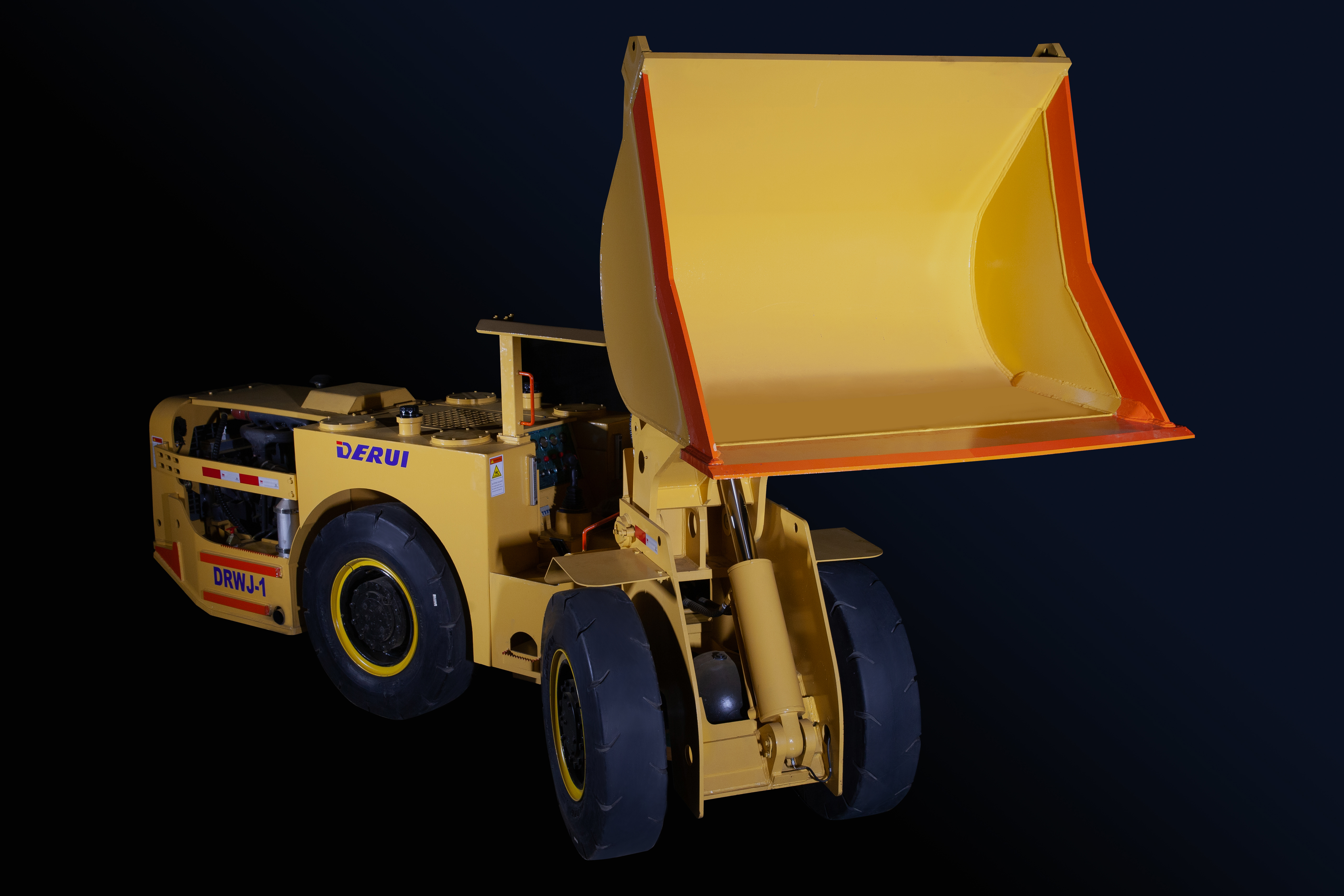

The maximized capacity gombined with a very light machine, relative to its size, reduces the cost per tonne and offers superior productivity. One of the definite highlights of DRWJ-1 is the new powerful hydrostatic transmission.lt is efficient and easy to use, which helps the operator to stay focused and prgductive.

The new hydro-static drivetrain eliminates gear shifting and enables simple, stepless operation compared with a standard driveline. This makes DERUI DRWJ-1 a significantly easier loader to learn, even for an inexperienced operator. In addition to simplified operation, the hydrostatic transmission also helps to minimize maintenance and operating costs.

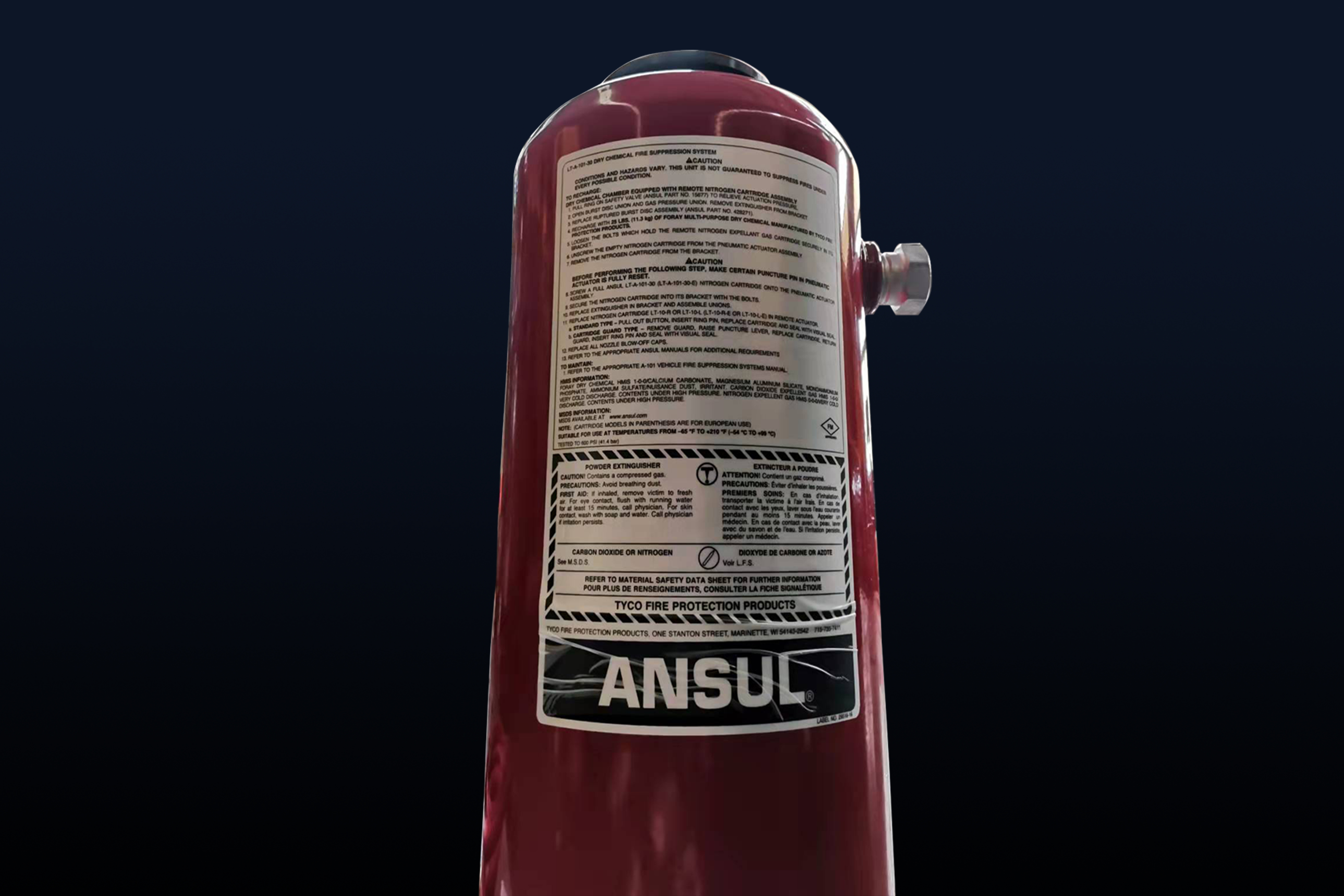

DERUI DRWJ-1 is designed for excellent maintainability: all daily servicing tasks can be performed on the ground level, reducing risk of slips, trips and falls. Powerful LED lights are standard equipment to improve visibility and avoid collisions with the wall, other equipment and people.

The DERUI DRWJ-1 is full of features which help mines maximize tonnes and minimize extraction costs. It has been engineered to optimize machine width, length and turning radius, enabling operation in more narrow tunnels and for lower operational costs.

Due to its relatively light weight and the possibility to disassemble the equipment for transport, the DERUI DRWJ-1 is a fit match for small-dimensioned construction sites, even if located in remote areas within challenging access.

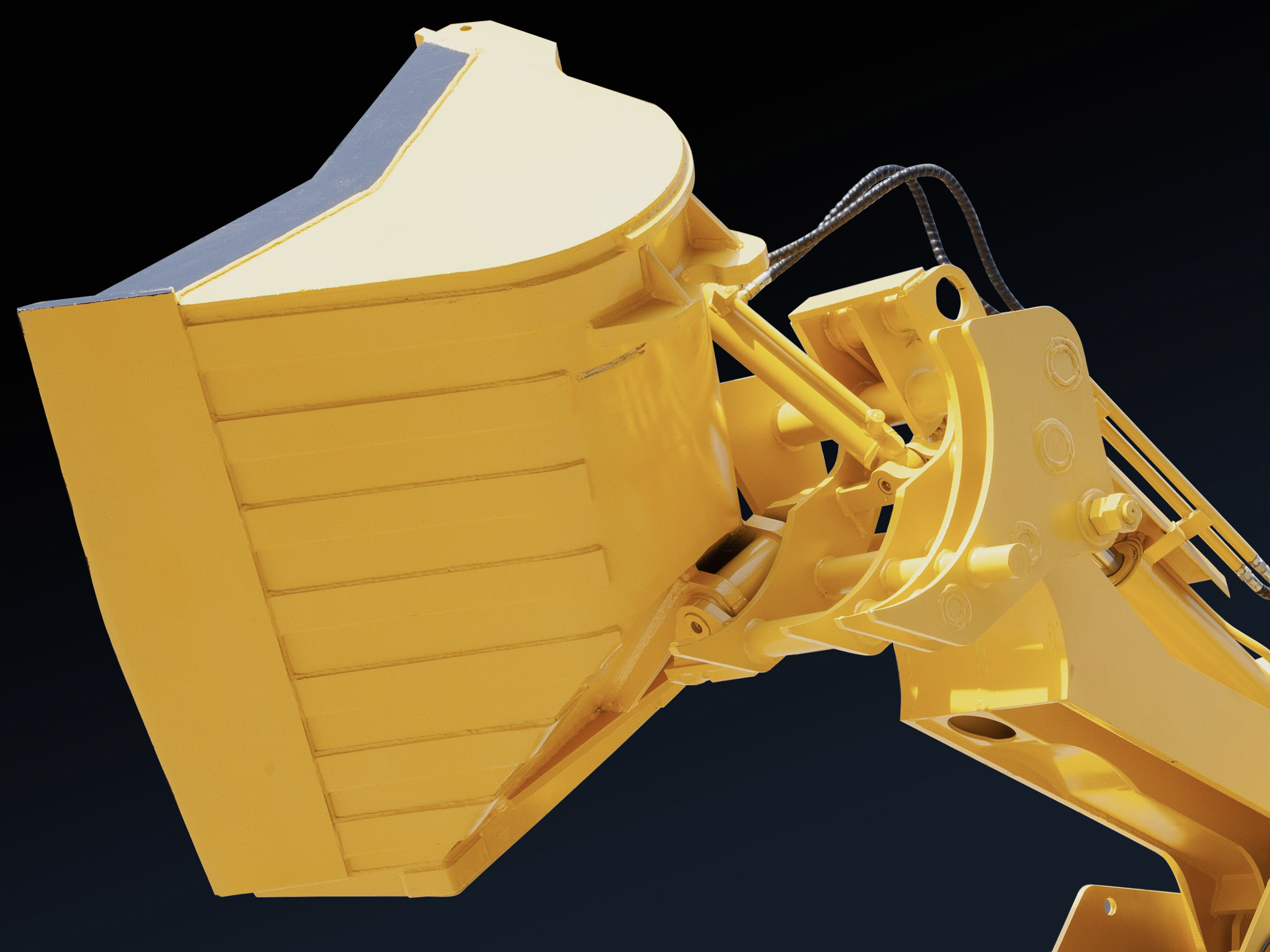

The hydrostatic powertrain also helps to provide a high breakout force and fast acceleration, enabling effective handling of larger rocks with fewer interruptions, even in challenging conditions.

The hydrostatic powertrain also helps to provide a high breakout force and fast acceleration, enabling effective handling of larger rocks with fewer interruptions, even in challenging conditions.

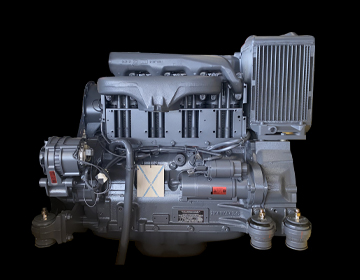

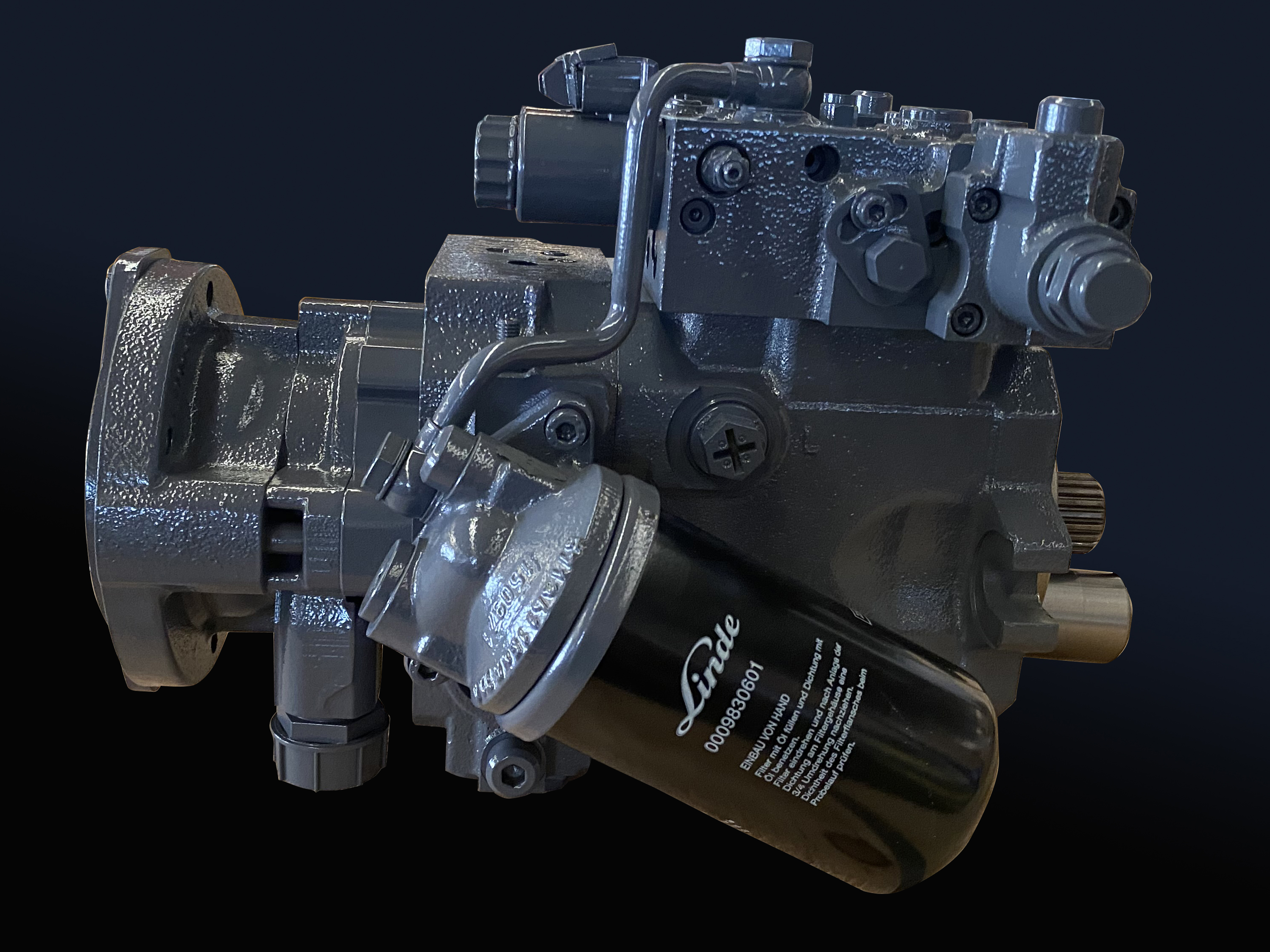

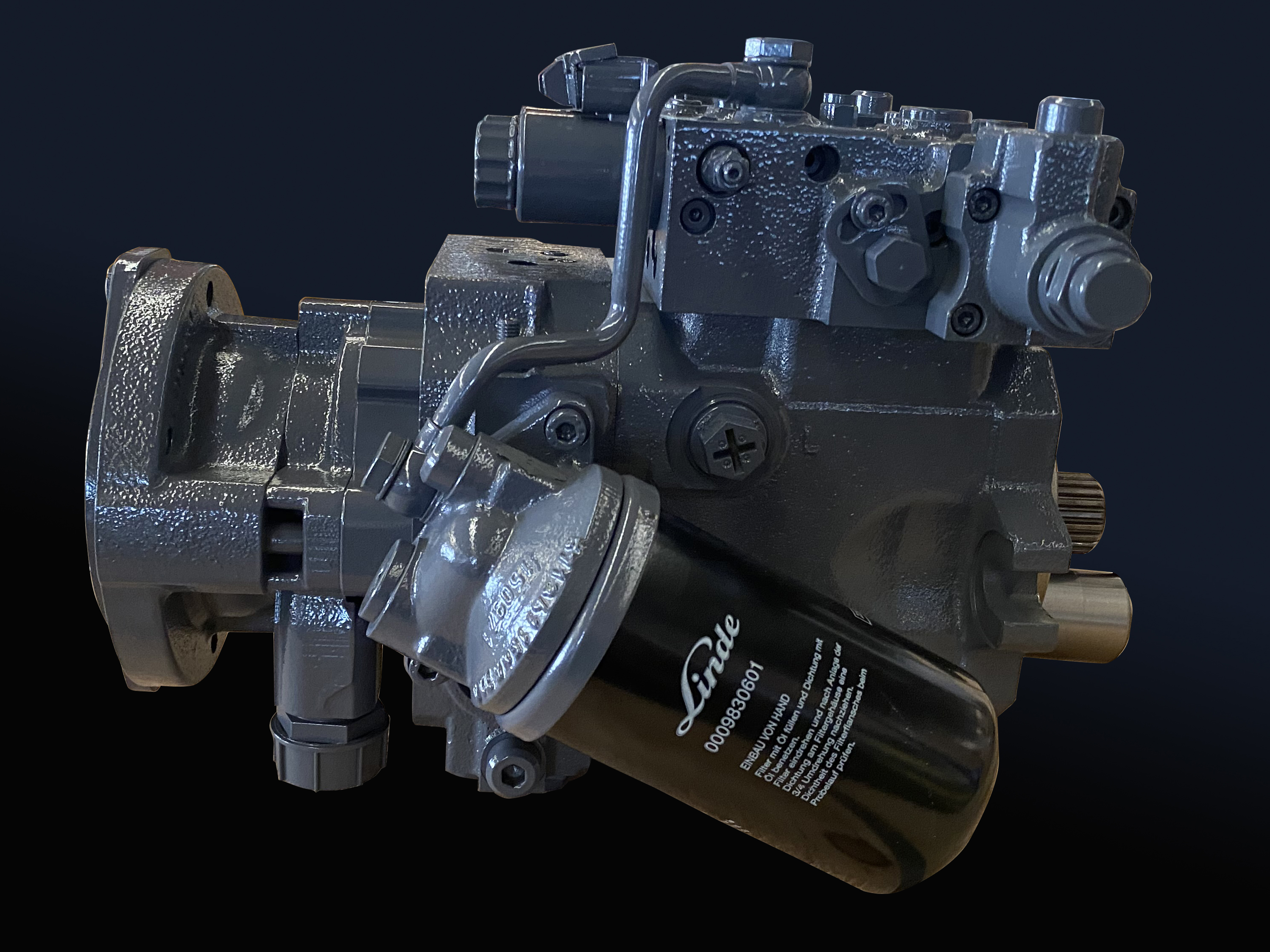

Using LINDE HPV 55 series independent variable pump originally made in Germany. Different from the variable pumps made by other manufacturers, the LINDE HPV 55 pump realizes the function of automatically adjusting the hydraulic displacement according to the change of the engine speed, thus operator no need to adjust the engine speed by pulling the cable by hands.

Using LINDE HPV 55 series independent variable pump originally made in Germany. Different from the variable pumps made by other manufacturers, the LINDE HPV 55 pump realizes the function of automatically adjusting the hydraulic displacement according to the change of the engine speed, thus operator no need to adjust the engine speed by pulling the cable by hands.

Our company is the only manufacturer in China that adopts high-end independent variable pump. With the system composed of self-regulated independent variable motor, absorbing the engine torque and power, perfectly combine the flexibility of the DRWJ-1 with the high reliability of the hydraulic pump.

Our company is the only manufacturer in China that adopts high-end independent variable pump. With the system composed of self-regulated independent variable motor, absorbing the engine torque and power, perfectly combine the flexibility of the DRWJ-1 with the high reliability of the hydraulic pump.

The drive axle adopts the new Enhanced and reinforced edition of PC15 axle, and the main components such as axle housing, differential, planetary gear, and half shaft have been optimized and reinforced. Compared with light-weight axles on the LHDs at it class from other Chinese manufacturers, it is sturdy and durable, with high impact strength, reducing the failure rate.

The drive axle adopts the new Enhanced and reinforced edition of PC15 axle, and the main components such as axle housing, differential, planetary gear, and half shaft have been optimized and reinforced. Compared with light-weight axles on the LHDs at it class from other Chinese manufacturers, it is sturdy and durable, with high impact strength, reducing the failure rate.

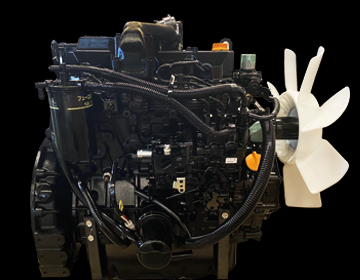

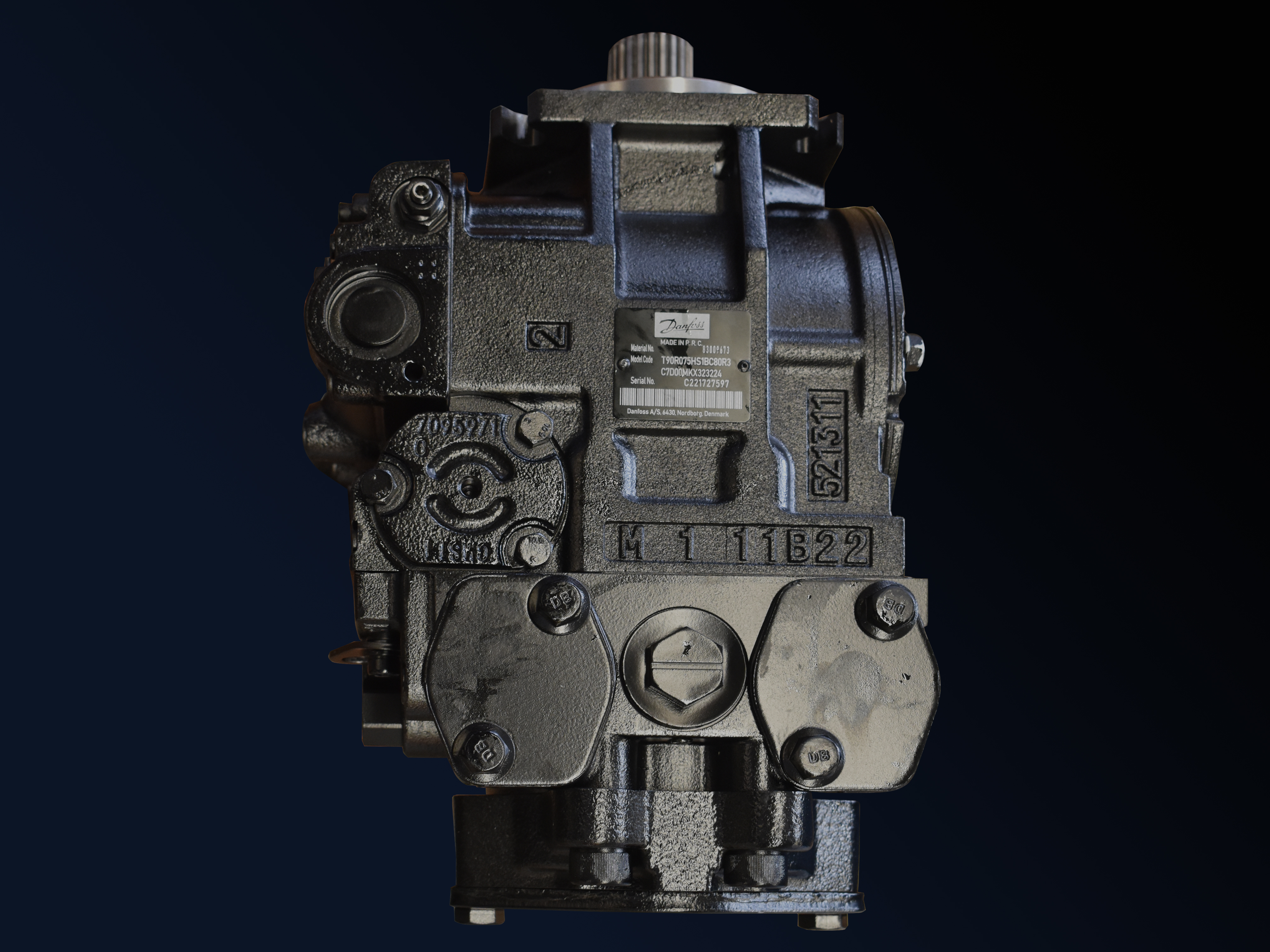

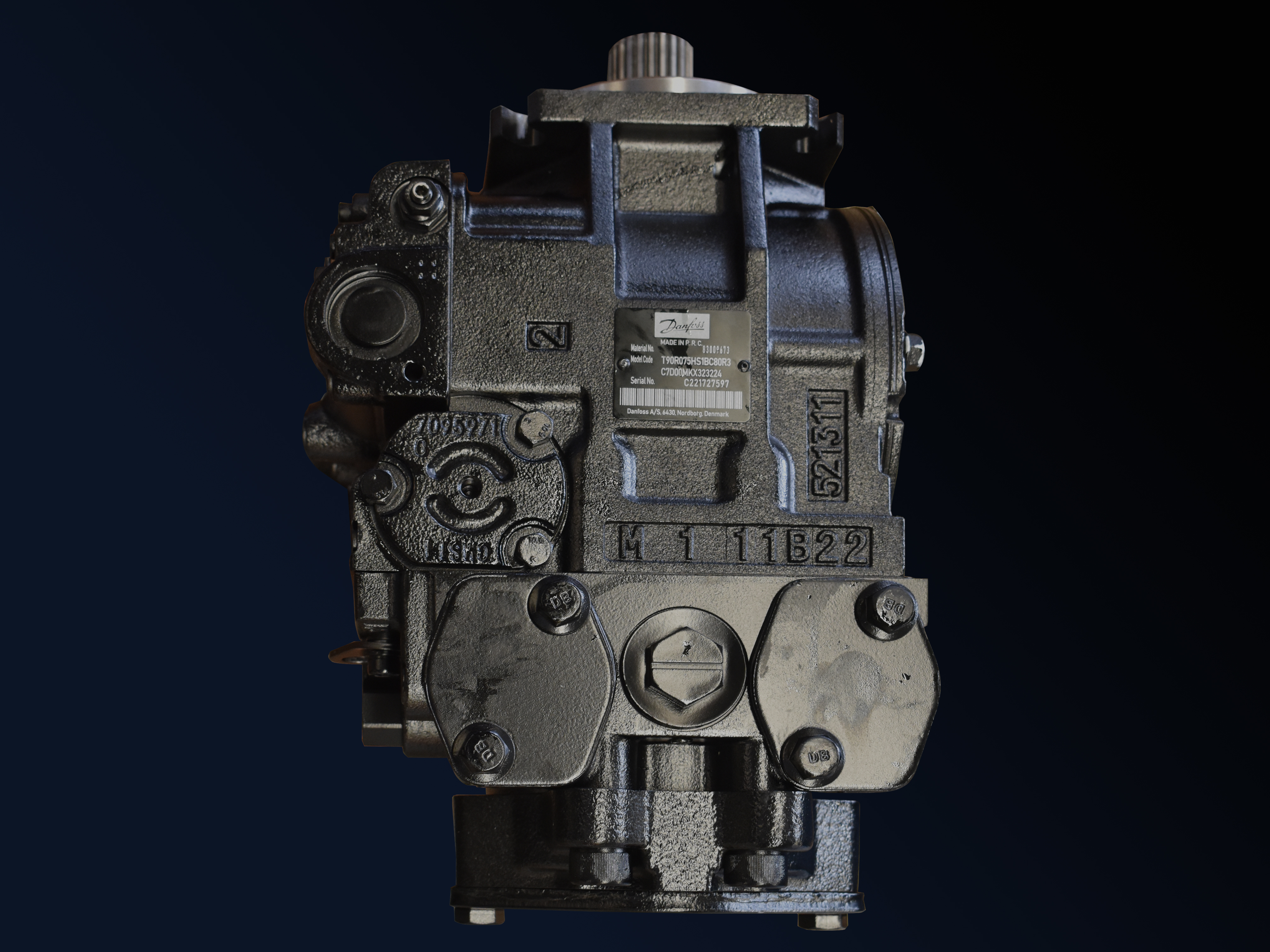

We always keep an alternative option of the axial piston pump for those end-users who are use to adjust the vehicle speeds by operating lever manually, which is the DANFOSS T90R075. The manual displacement control is a high gain control: With only small movement of the control handle (input signal), the servo valve moves to full open position porting maximum flow to the servo cylinder.

We always keep an alternative option of the axial piston pump for those end-users who are use to adjust the vehicle speeds by operating lever manually, which is the DANFOSS T90R075. The manual displacement control is a high gain control: With only small movement of the control handle (input signal), the servo valve moves to full open position porting maximum flow to the servo cylinder.

The DRWJ-3 and DRWJ-3.5 are equipped with the latest safety ROPS/FOPS cabin/canopy.The closed cabin is air-conditioned and noise re.sistant. It also includes laminated safety glass windows, Large window openings for increased visibility;

Large grab handles on both sides to provide 3-point access to cab and machine.

, anti-slip steps and an emergency exit.The cabin door includes a door lock and latch mechanism with an interock switch which automatcal-ly applies brakes when the door is opened.

Controls, levers, switches and gauges positioned to maximize productivity and minimize fatigue.

This loader is fited with an adjustable low frequency suspension seat with two-point seat belt as standard.Padded arm rests and adjustablejoysticks can be configured to suit the operator. The electro-hydraulic joystick controls for steering and boom

movements eliminate hydraulic hoses inside the operator's compartment and reduce potential hydraulic hazard.

Service brakes are spring applied; hydraulically operated multidisc wet brakes on allwheels. Two independent circuits: one for the front and one for the rear axle. Servicebrakes also function as an emergency and parking brake.Four corner oil-cooled brakingsystem provides excellent control.This system assures braking in the event of loss of hy-draulic failure.

Two emergency stop buttons on the left and right sides of the rear of the equipment,and one emergency stop button inside the cabin. Wheel chocks and brackets are op-tional.

Designed for quick and easy servicing. Simplified service and maintenance featuresreduce downtime,allowing the machine to spend less time being serviced and moretime being productive.Thanks to an easily serviced machine - easy access to all dailyservice points, saving time, reducing cost of operation and improving the service life.

The control panel for the DRWJ-3 is designed to be easy-to-use and

informative. All the data and information your operators need to perform,such as auto-generated diagnostic measurements, adjustments,and livedata readouts, is readily accessible on a sleek control panel.

The Murphy PV780 is a 7-inch full-color LCD display with lP69 waterproofgrade standard.

the world's leading LCD technology makes PV780 clearly visible under directsunlight.

The Murphy PV780 LCD display is durable in harsh environments. Compatiblewith Euro lV emission standards and support multiple languages.

Views of DERUI DRWJ-1 at the mine site